Layar Panggantos kanggo Derrick 500 PWP

Katrangan

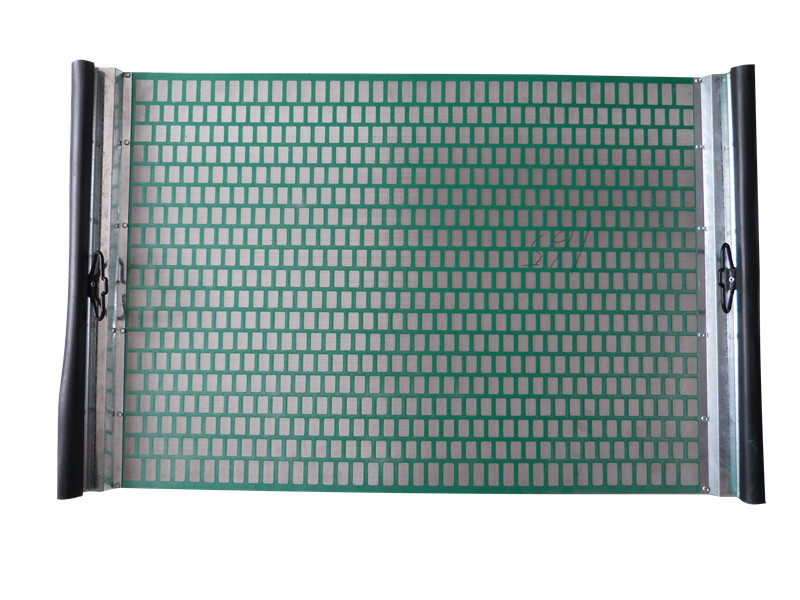

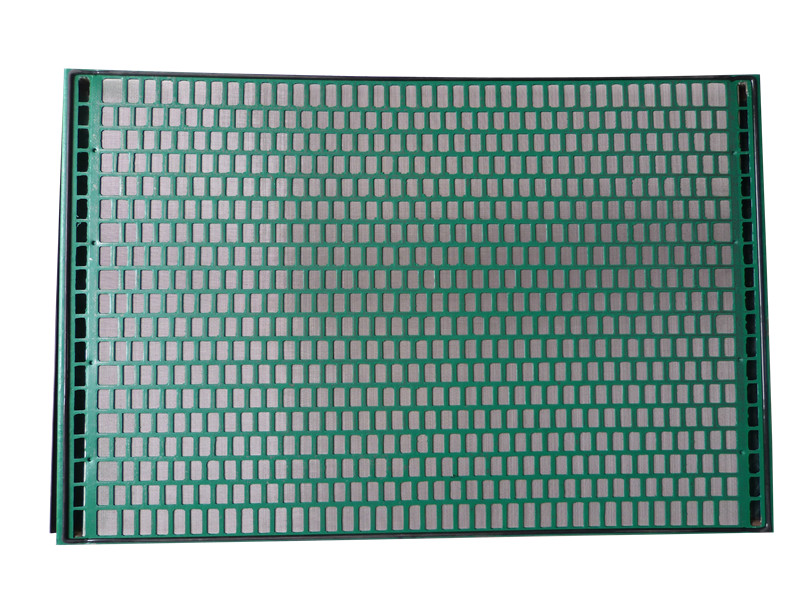

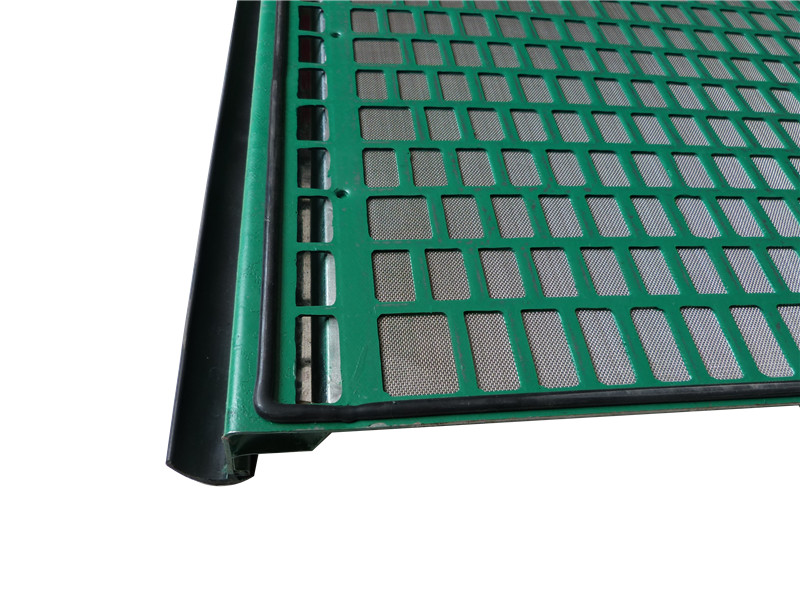

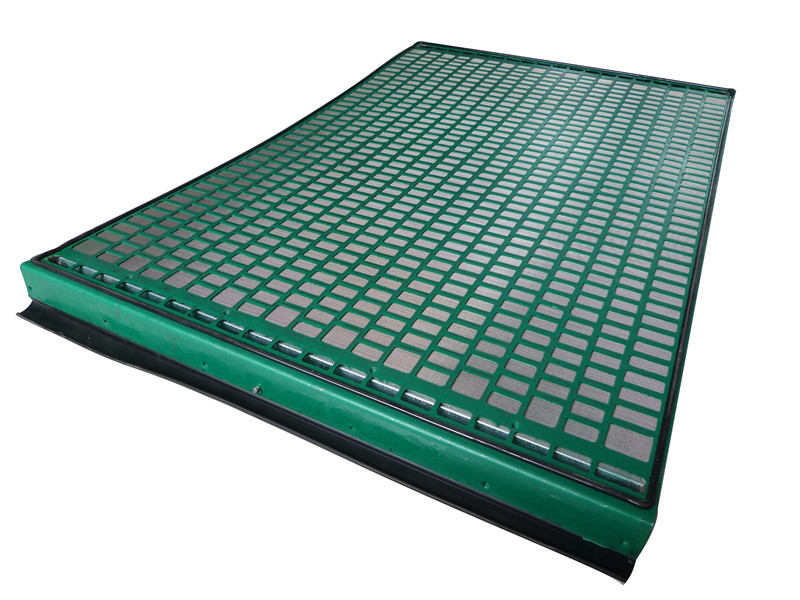

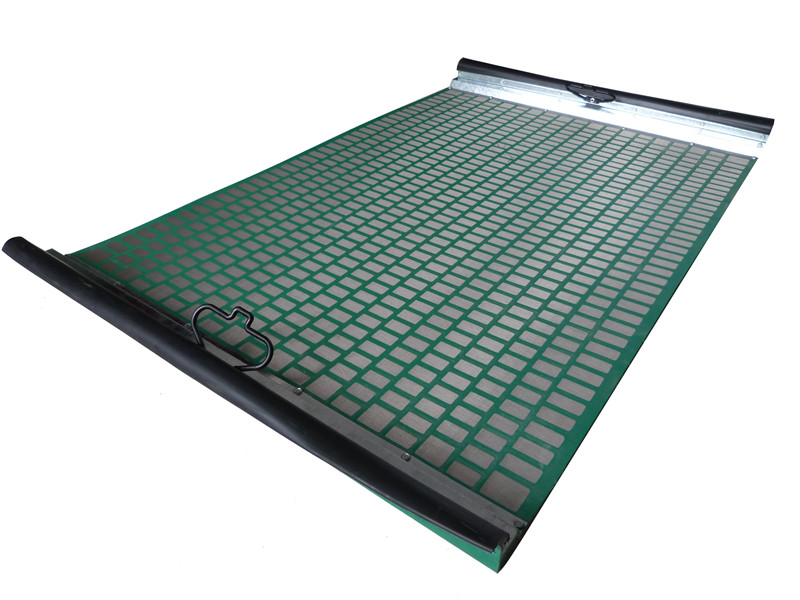

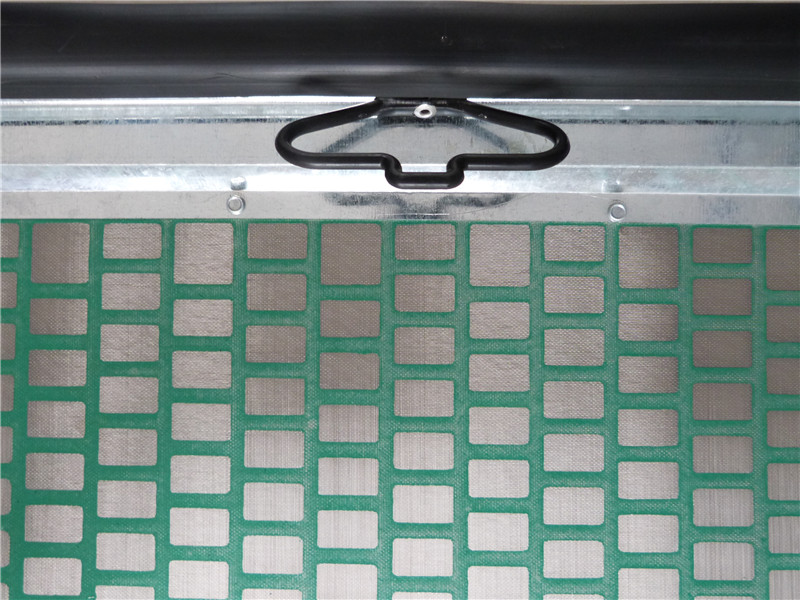

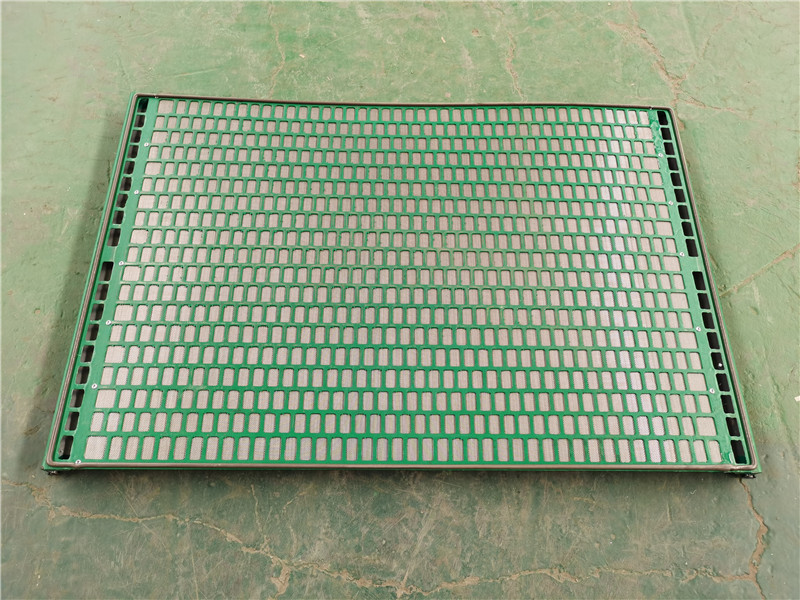

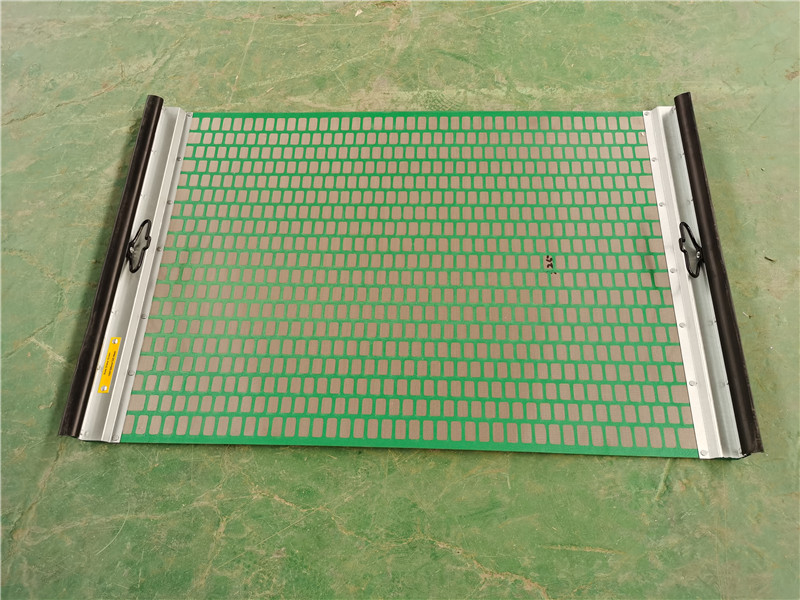

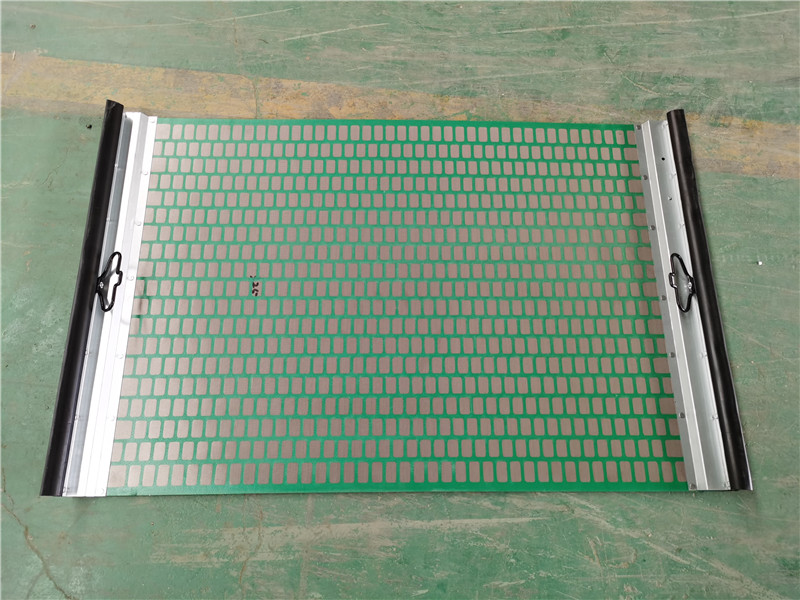

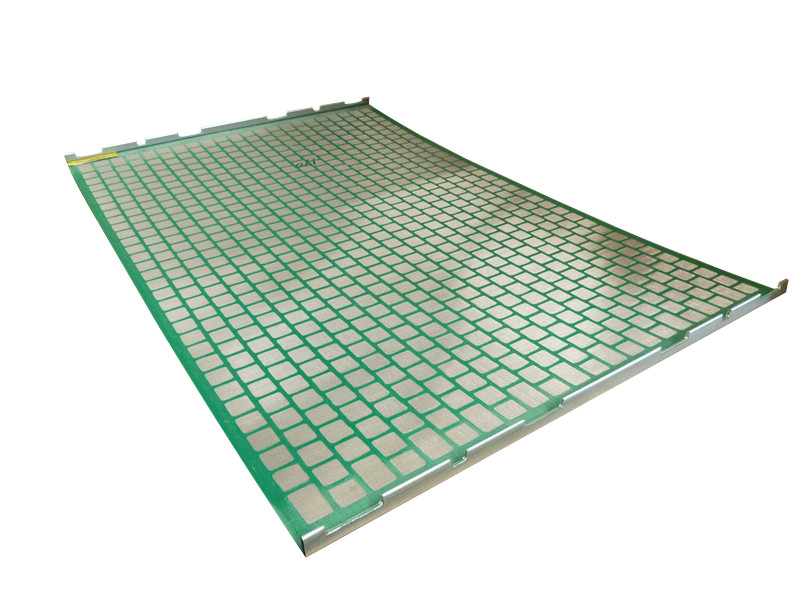

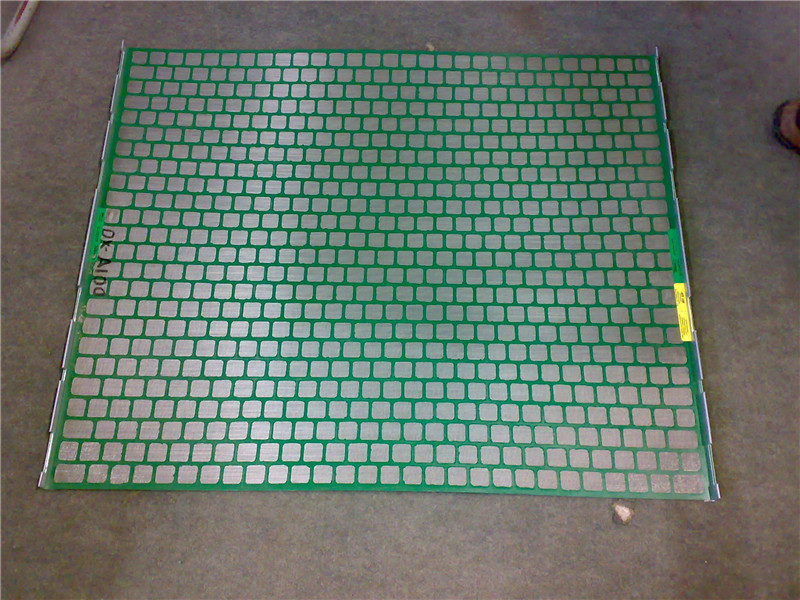

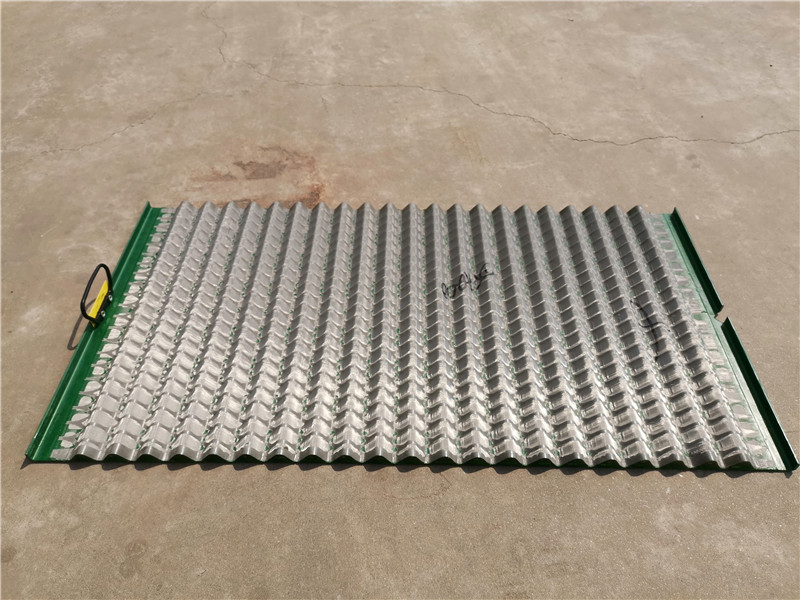

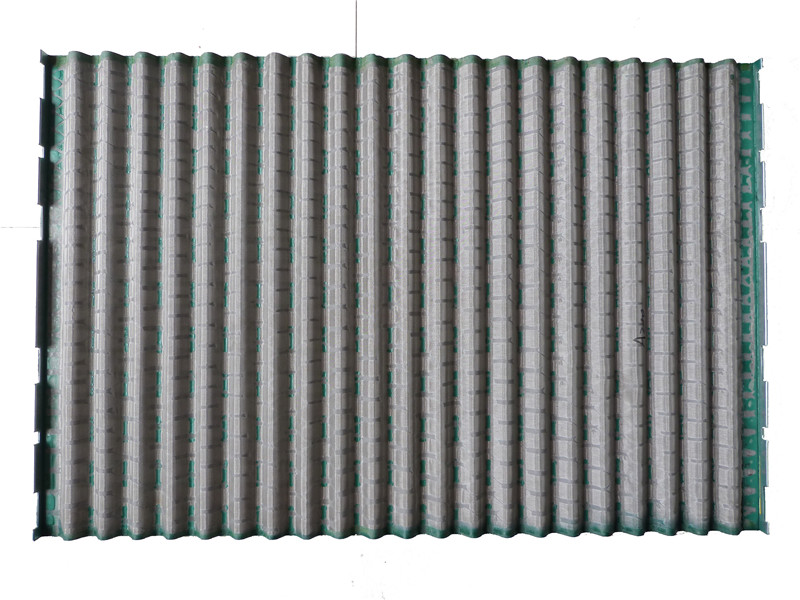

FLC 500 flat shaker layar dirancang kanggo layar panggantos saka Derrick FLC 500 shale shakers seri.Iki dibangun kanthi rong utawa telung lapisan kain bolong kawat baja tahan karat 304 utawa 316, lan banjur digabungake karo piring backing baja.Layar FLC 500 PWP nduweni sistem tegangan kunci cepet siji sisih sing nyuda wektu panggantos panel.

Model Shale Shaker sing bisa diadaptasi

KET-PWP 500 layar shaker digunakake minangka layar sulih kanggo

Derrick FLC (Flo-line Cleaner) 503 shaker.

Derrick FLC (Flo-line Cleaner) 504 shaker.

Derrick FLC (Flo-line Cleaner) 503 pangatusan shaker.

Derrick FLC (Flo-line Cleaner) 504 pangatusan shaker.

Derrick FLC (Flo-line Cleaner) 513 shaker.

Derrick FLC (Flo-line Cleaner) 514 shaker.

Derrick FLC (Flo-line Cleaner) 513 VE (Ekstrak Uap).

Derrick FLC (Flo-line Cleaner) 514 VE (Ekstrak Uap).

Kaluwihan Kompetitif

Stainless steel 304/316 wire mesh kanggo umur dawa.

Sistem tension kunci cepet, efek trapping (dreg) sing apik.

Gampang mriksa layar, mbusak, lan instalasi.

Tambah kapasitas shaker lan nyuda mundhut lendhut.

Sistem kontrol biaya ilmiah & cukup kanggo rega sing kompetitif.

Tingkat aliran sing luwih dhuwur tanpa ngorbanake integritas titik potong.

API RP 13C (ISO 13501) tundhuk.

Persediaan sing nyukupi ing wektu paling cendhak kanggo nyukupi panjaluk pelanggan.

Garansi: 1 taun.

Urip Kerja: 400-450 jam.

Parameter kinerja

| Jeneng layar | Tipe Mesh | Jeneng API RP 13C | Nomer konduktansi | Pemisahan D100 (mikron) | Lapisan No. | Area Non-Kosong (sq.ft) |

|---|---|---|---|---|---|---|

| KET-PWP 500-A325 | DF | API 325 | 0.39 | 44 | 2/3 | 4.05 |

| KET-PWP 500-A270 | DF | API 270 | 0.67 | 57 | 2/3 | 4.05 |

| KET-PWP 500-A230 | DF | API 230 | 0.71 | 68 | 2/3 | 4.05 |

| KET-PWP 500-A200 | DX | API 200 | 1.32 | 73 | 2/3 | 4.05 |

| KET-PWP 500-A170 | DX | API 170 | 1.34 | 83 | 2/3 | 4.05 |

| KET-PWP 500-A140 | DX | API 140 | 1.89 | 101 | 2/3 | 4.05 |

| KET-PWP 500-A120 | DX | API 120 | 1.89 | 134 | 2/3 | 4.05 |

| KET-PWP 500-A100 | DX | API 100 | 2.66 | 164 | 2/3 | 4.05 |

| KET-PWP 500-A80 | DX | API 80 | 2.76 | 193 | 2/3 | 4.05 |

| KET-PWP 500-A70 | DX | API 70 | 3.33 | 203 | 2/3 | 4.05 |

| KET-PWP 500-A60 | DX | API 60 | 4.1. | 268 | 2/3 | 4.05 |

| KET-PWP 500-A50 | DX | API 50 | 5.17 | 285 | 2/3 | 4.05 |

| KET-PWP 500-A40 | DX | API 40 | 8.64 | 439 | 2/3 | 4.05 |

| KET-PWP 500-A35 | DX | API 35 | 9.69 | 538 | 2/3 | 4.05 |

| KET-PWP 500-A20 | DF | API 20 | 10.88 | 809 | 2/3 | 4.05 |

| * D100: Partikel ukuran iki lan luwih gedhe biasane bakal dibuwak.* API: Cocog API sieve padha karo API RP 13C.* Konduktansi No.: Iki nggantosi ease karo Cairan bisa mili liwat layar.Nilai luwih gedhe nuduhake volume handing luwih. | ||||||